Tough As Nails: Exploring The World Of Construction Boots

Key Takeaways:

- Boot Type Breakdown: Understand how different construction boot types—like steel toe, composite, and waterproof—meet various job site demands.

- Beyond Basic Safety: Learn how to assess key features that go beyond safety, including comfort, fit, and weather resistance.

- Maintenance Matters: Get practical tips for extending the life of your boots through regular care, maintenance, and smart buying decisions.

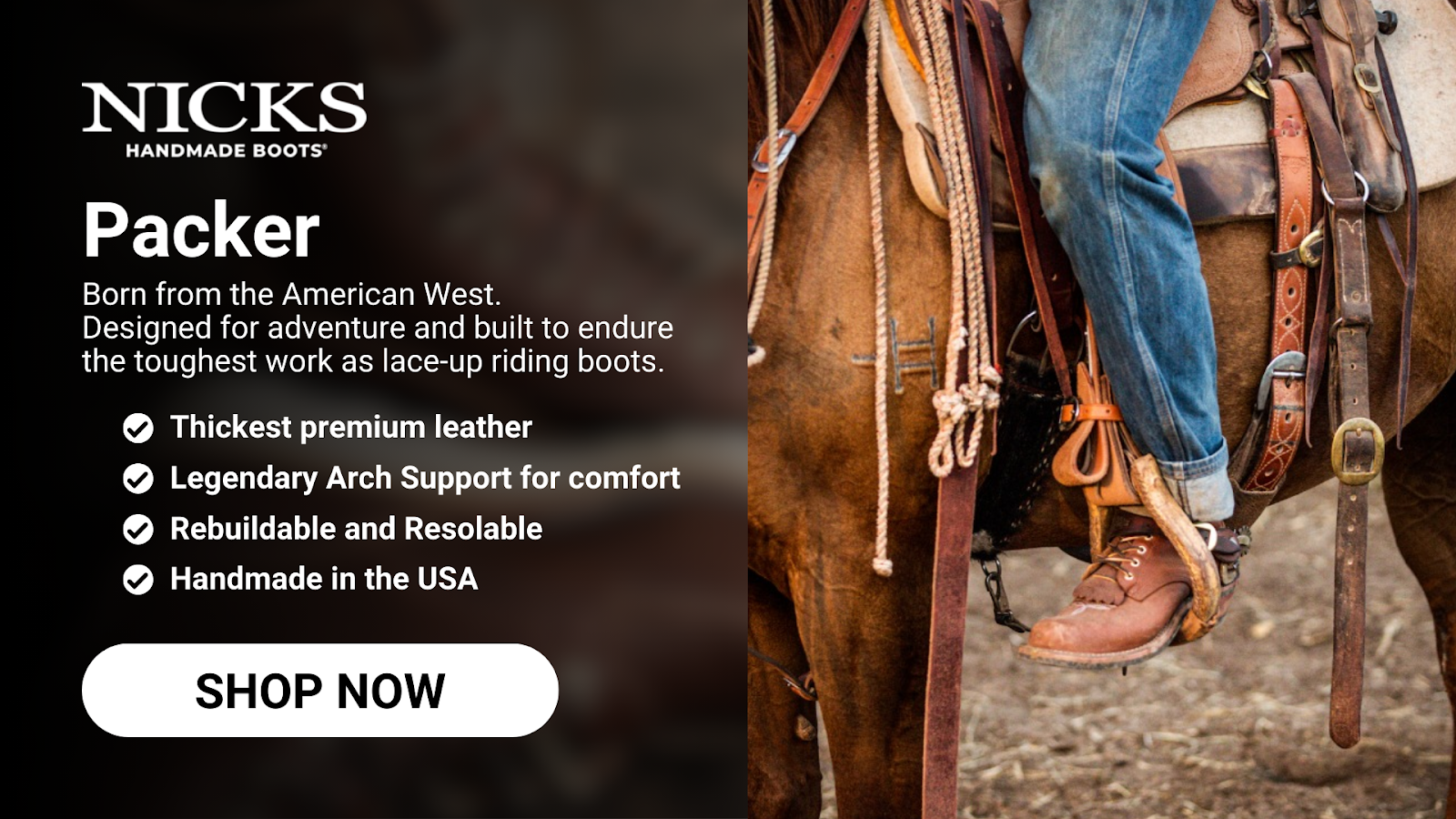

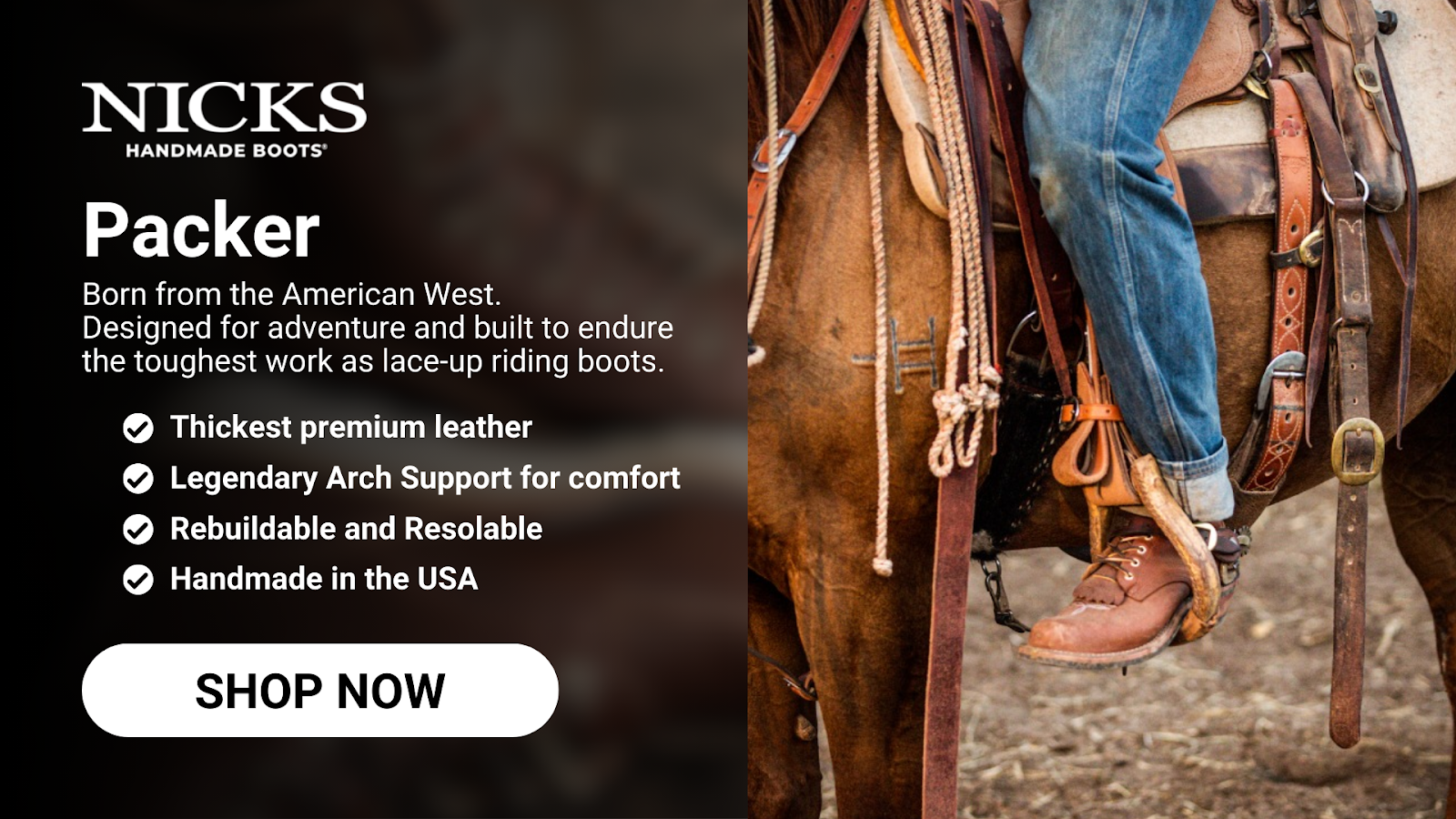

At Nick’s Boots, we don’t just make boots—we build them. Handcrafted in Spokane, Washington, every pair that leaves our workshop is a testament to over half a century of American bootmaking tradition. From the first cut of leather to the final stitch, our legacy is built on craftsmanship, durability, and the kind of quality that can only come from real hands and real grit. We're not in the business of disposable footwear—we’re in the business of making boots that work as hard as the people who wear them.

Construction boots are more than just another item on a job site checklist—they’re your first line of defense and your foundation, shift after shift. Whether you're scaling scaffolding, walking rebar, or grinding out 12-hour days on unforgiving concrete, your boots have to keep up. In a world of mass production, it’s easy to overlook the importance of the right fit, the right build, and the right protection. But real work demands real gear, and the best construction boots are built with purpose—not shortcuts.

In this piece, we’ll be exploring what makes a construction boot truly “tough as nails”—from critical features and boot types to care tips and how to choose the right pair for your line of work.

Why Construction Boots Matter

Construction sites are some of the most hazardous work environments, filled with heavy machinery, sharp debris, uneven surfaces, and potential electrical hazards. In such conditions, the right footwear isn’t just a comfort choice—it’s a critical piece of safety equipment.

Construction boots are designed to protect the feet from common workplace dangers such as falling objects, punctures, slips, and exposure to hazardous materials. Without the proper boots, workers are far more vulnerable to injury, which can lead to lost time, medical bills, and long-term damage.

But it's not just about protection. Quality construction boots also provide essential support for long hours of standing or walking on hard, unstable ground. Features like padded insoles, arch support, and ankle stability can help prevent fatigue and reduce the risk of chronic foot and back pain. In many cases, investing in a reliable pair of construction boots is just as crucial as wearing a hard hat or high-visibility vest.

Key Features Of The Best Construction Boots

Not all construction boots are created equal. When looking for the best pair, certain features set top-tier boots apart from the rest—both in terms of safety and comfort.

Steel Or Composite Toe Protection

This is the hallmark of any good construction boot. Steel toes offer maximum protection against impact and compression, while composite toes (made from materials like Kevlar or carbon fiber) provide similar protection with less weight and no metal, which is useful around electrical hazards.

Slip-Resistant Soles

Slips and falls are one of the most common workplace accidents. The best boots feature soles made from high-traction rubber or polyurethane that can grip slick or uneven surfaces, whether it's wet concrete or loose gravel.

Waterproof And Weather-Resistant Materials

Construction work doesn’t stop for the weather. Boots made with waterproof membranes like Gore-Tex or treated leather keep feet dry and warm in wet or muddy conditions.

Electrical Hazard (EH) Rating

For electricians or workers near live circuits, EH-rated boots are essential. These are designed to reduce the risk of electric shock from live wires on the ground.

Durable Construction Materials

Full-grain leather, Goodyear welt construction, and reinforced stitching contribute to a boot’s longevity and resistance to wear and tear in rugged environments.

Comfort Features

Padded collars, cushioned midsoles, breathable linings, and ergonomic insoles ensure that boots aren’t just protective—but also comfortable enough for long shifts.

Types Of Construction Boots

There’s a wide variety of construction boots available, each tailored for specific tasks, environments, or user preferences. Knowing the differences can help workers choose the right boot for the job.

Steel Toe Boots

These are the classic choice for heavy-duty protection. Steel toe boots are ideal for environments where falling objects or compression hazards are a concern, such as demolition or warehouse work. They offer maximum durability, though they tend to be heavier.

Composite Toe Boots

Made from non-metal materials like plastic, Kevlar, or carbon fiber, composite toe boots are lighter and non-conductive. They're great for electrical work or cold environments, as they don’t get as cold as steel.

Insulated Boots

For cold climates or outdoor winter jobs, insulated construction boots provide warmth and protection. The insulation is usually rated by grams—higher ratings for colder conditions.

How To Choose The Right Pair

Choosing the right construction boots goes beyond just picking a popular style or brand. It’s about aligning the features of the boot with the specific demands of the job and personal comfort needs.

Assess Your Work Environment

Start by identifying the hazards in your workplace. Do you work around heavy machinery, wet surfaces, or electrical equipment? Each of these environments requires specific safety features like steel toes, slip-resistant soles, or EH ratings.

Consider Comfort for Long Hours

A boot might be tough, but if it causes foot pain after a few hours, it’s not doing its job. Look for boots with cushioning, arch support, and breathable linings—especially if you spend 8 to 12 hours a day on your feet.

Fit Matters

A poor fit can lead to blisters, fatigue, or even injury. Boots should offer a snug fit without pinching. Always try them on with the same type of socks you’ll wear on the job, and walk around to ensure there's enough room in the toe box and support around the heel.

Evaluate Durability And Build Quality

Look for high-quality materials like full-grain leather, reinforced eyelets, and heavy-duty stitching. Boots that feature Goodyear welt construction often last longer and can be resoled if needed.

Think About Weather And Conditions

In colder climates, insulated boots will keep your feet warm, while waterproofing is essential in wet or muddy areas. Breathable fabrics are a must for hot weather to avoid overheating and moisture buildup.

Break-In Period

Don’t forget that even the best boots might need a break-in period. Plan ahead to wear them for shorter periods initially before using them full-time on the job site.

Care And Maintenance Tips

A quality pair of construction boots is an investment—and with proper care, they can last for years, even in the toughest conditions. Regular maintenance not only extends their lifespan but also keeps them performing at their best.

Clean Them Regularly

After each use, especially in muddy or dusty environments, brush off dirt and debris with a soft brush. Use a damp cloth for tougher grime. For leather boots, a specialized leather cleaner helps preserve the material.

Dry Them Properly

Never dry boots directly with high heat like a space heater or open flame—it can damage the materials. Instead, remove the insoles and laces, and let them air dry. You can also stuff them with newspaper to absorb moisture more quickly.

Condition The Leather

Leather boots need conditioning every few weeks or months, depending on use. This keeps the leather supple, prevents cracking, and maintains water resistance. Use a leather conditioner or mink oil sparingly to avoid over-softening.

Waterproof When Necessary

If your boots aren’t already waterproof, or if the waterproofing has worn off, apply a waterproofing spray or wax regularly to maintain resistance, especially before exposure to wet conditions.

Inspect For Wear And Tear

Check for signs of sole separation, worn tread, or damage to the toe cap. Addressing small issues early—like re-gluing a sole or replacing worn insoles—can prevent the need for full replacements.

Store Them Right

Keep boots in a cool, dry place when not in use. Avoid leaving them in direct sunlight or damp areas, as this can cause materials to degrade faster.

Final Thoughts

Construction boots are more than just rugged footwear—they're essential tools that protect, support, and endure the daily grind of demanding work environments. Whether you're navigating a construction site, climbing scaffolding, or simply spending long hours on your feet, the right pair of boots can make all the difference in safety and performance.

By understanding the different types of boots, identifying key features, and committing to proper care, workers can find a pair that truly meets their needs. Durability, comfort, and protection shouldn’t be compromised—and with the right approach, you’ll find boots that are tough as nails and ready for anything the job throws your way.

Read Also:

Frequently Asked Questions About Construction Boots

What materials are considered the most durable for construction boots?

While leather is widely known for its strength, longevity, and ability to mold to the foot, it's not the only tough material out there. Thermoplastic polyurethane (TPU) outsoles and Kevlar-reinforced fabrics add exceptional resistance to cuts, chemicals, and abrasions, making them ideal for the harshest job site environments.

Can construction boots be used for hiking or casual wear?

Technically, yes—but it’s not ideal due to their heavy-duty construction. These boots are built with thick soles, rigid support, and toe protection, which can make walking long distances or wearing them casually more tiring and less comfortable than using activity-specific footwear.

Are there vegan options for construction boots?

Yes, vegan construction boots are now widely available and designed to meet the same safety standards as traditional leather boots. They use innovative synthetic materials such as high-grade microfiber, mesh, and rubber to provide water resistance, breathability, and structural integrity without animal by-products.

How often should construction boots be replaced?

For heavy daily use, construction boots typically last between 6 to 12 months before performance starts to decline. Key signs to replace them include worn treads, reduced arch support, cracking materials, or diminished toe protection—even if they still look usable on the outside.

Do construction boots expire or degrade when unused?

Yes, construction boots can break down over time even without wear, especially if stored improperly. Elements like adhesives and rubber soles can dry out or weaken, which compromises the boot's safety features and comfort once put back into use.

Are metal-free boots as safe as steel toe boots?

Yes—when they meet proper safety certifications like ASTM or EN ISO, metal-free options such as composite toe boots provide equivalent impact and compression resistance. They're also lighter, non-conductive, and often preferred in environments with metal detectors or cold climates where steel can freeze.

Can orthotic insoles be used in construction boots?

Absolutely—many modern work boots come with removable footbeds specifically to accommodate custom orthotics or over-the-counter insoles. This allows wearers to enhance comfort, correct posture, or address foot-related health issues without sacrificing safety.

How do I know if a boot is rated for electrical hazard protection?

Look for an “EH” or “Electrical Hazard” marking on the product label, tag, or inside the boot collar. This designation means the footwear has been tested to protect against electrical shock by insulating the wearer from live circuits up to 18,000 volts under dry conditions.

What’s the difference between ASTM and OSHA standards for boots?

ASTM (American Society for Testing and Materials) outlines the performance criteria for protective footwear, such as impact resistance and puncture protection. OSHA (Occupational Safety and Health Administration), on the other hand, enforces workplace safety rules and references ASTM standards to ensure employers provide compliant footwear for hazardous jobs.