Best Boots For Linemen: Built For Safety, Support & Tough Terrain

Key Takeaways:

- Look for specialized safety features: Electrical hazard protection, reinforced toe boxes, and puncture-resistant soles are essential for linemen to avoid life-threatening risks and enhance workplace safety.

- Focus on durability and comfort: Boots made from full-grain leather, heavy-duty stitching, and supportive shanks are key to ensuring long-term comfort and reliability during long shifts on rugged terrain.

- Consider custom vs. stock boots: Custom boots offer a personalized fit for maximum comfort and safety, while stock boots provide immediate availability and proven performance for the everyday lineman.

Every day is a test of grit and resolve in the world of linemen—a constant battle with gravity, the elements, and unforgiving terrain. The stakes are high: climbing poles in a thunderstorm, traversing wet grass or rocky slopes, or working atop steel towers where one misstep could mean disaster. In this line of work, ordinary footwear simply doesn’t cut it. What you put on your feet is more than just gear—it’s a vital line of defense.

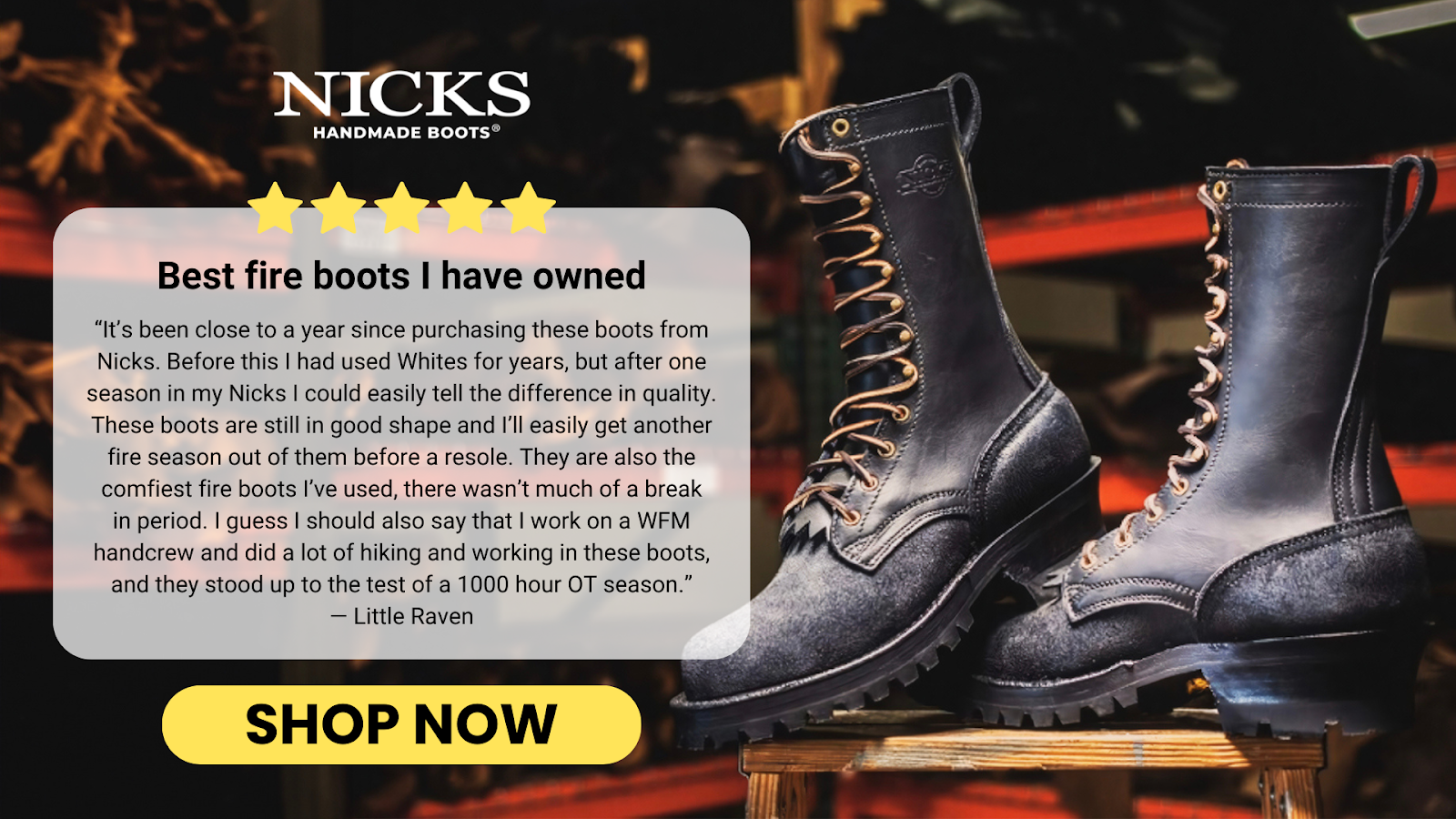

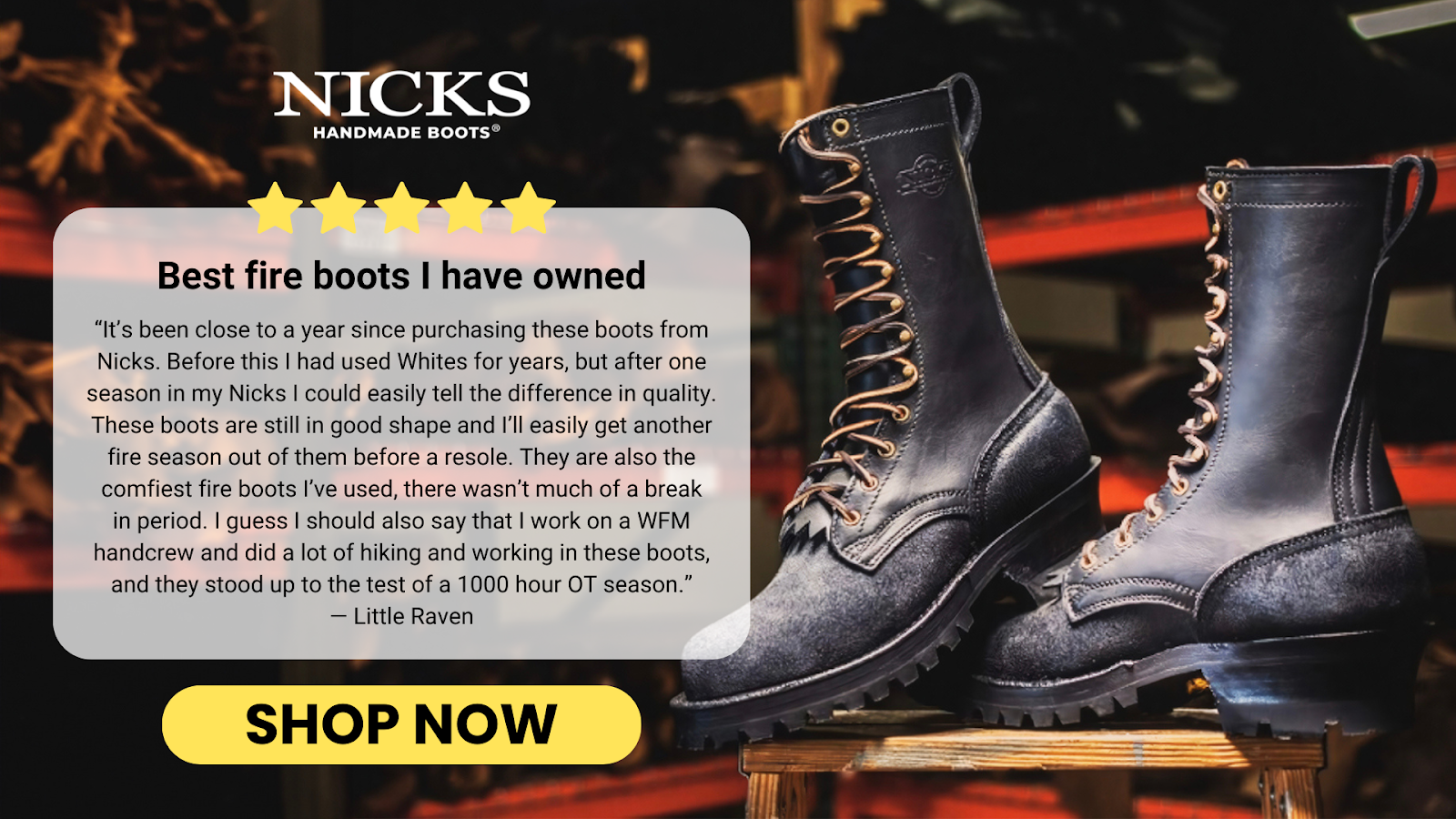

At Nicks Boots, we understand that legacy. With six decades of experience and a commitment to American craftsmanship, our boots are built from the ground up—every stitch, eyelet, and sole reflecting our heritage as artisan bootmakers.

In this guide, we’ll cut through the noise to help you find the best boots for linemen—footwear that stands up to rugged terrain, long hours, and the relentless test of the trade.

Why Linemen Need Specialized Boots For The Job

Working as a lineman is more than just a job—it's a daily test of skill, focus, and resolve, played out in some of the most demanding conditions imaginable. The right pair of boots is not a luxury, but a crucial safety equipment. Ordinary footwear doesn’t measure up when you’re suspended high above the ground, managing powerful electrical currents, and contending with unpredictable terrain.

Protection From Electrical Hazards

Linemen regularly operate near live wires and high-voltage equipment. Specialized boots come with electrical hazard-rated soles and insulating materials, offering a critical defense against accidental shocks. This extra protection can mean the difference between a close call and a life-altering incident.

Superior Ankle And Arch Support

Climbing poles, ladders, and navigating uneven ground demands exceptional support. Boots designed for linemen feature reinforced ankle structures and contoured arch support, reducing fatigue during long shifts and stabilizing every step. This firm support is essential for preventing strains and injuries—common risks in such a physically taxing line of work.

Enhanced Traction For Unpredictable Terrain

Mud, wet grass, gravel, and even icy surfaces are all part of a lineman’s everyday landscape. Slipping isn’t an option when safety is at stake. Quality lineman boots boast aggressive, rugged outsoles that grip firmly to both man-made and natural surfaces, delivering the traction needed to move confidently, whether ascending a pole or working along a roadside.

Durability And All-Weather Performance

Lineman boots are built for the long haul, crafted from tough full-grain leathers and heavy-duty stitching. Water resistance, temperature regulation, and abrasion resistance ensure these boots hold up through months and years of daily punishment. Reliable footwear minimizes downtime caused by worn-out gear and provides peace of mind in the harshest environments.

What Makes The Best Boots For Linemen? Key Features To Look For

The best boots for linemen are built to deliver unwavering stability, protection, and comfort in environments where safety and reliable support are non-negotiable. Here’s what to look for when selecting boots engineered for these demanding tasks:

Extreme Durability And Quality Construction

Linemen need footwear that withstands abrasion, water, oil, and the repeated stress of climbing and standing on unforgiving surfaces. Look for boots constructed using premium full-grain leather, heavy-duty stitching (often utilizing Goodyear welt construction), and robust outsoles designed for harsh terrain. Superior craftsmanship ensures not just longevity but also consistent support under extreme use.

Advanced Safety Features

Electrical hazard (EH) ratings and puncture-resistant soles are critical for reducing on-the-job risks. Boots should feature reinforced toe boxes—either steel or composite—for protection against dropped tools and equipment, without adding excessive weight. Additionally, quality lineman boots provide insulation from electrical currents, an essential safeguard in this high-risk trade.

Exceptional Ankle And Arch Support

Frequent climbing and working at elevation put unique stress on the ankles and arches. Linemen’s boots are typically designed with a taller shaft, offering increased ankle protection and stability during climbs. A well-contoured, supportive arch structure helps stave off fatigue and ensures secure footing—even after work hours.

All-Terrain Traction

Uneven, slippery, and unpredictable surfaces demand outsoles that are slip-resistant and capable of digging into soil, gravel, and bark. Deep lug patterns and abrasion-resistant rubber compounds provide the necessary grip so that linemen can stay surefooted in every scenario, from steel ladders to muddy worksites.

Comfort And Custom Fit

Long shifts require boots that feel as good at the end of the day as they do at the start. Moisture-wicking linings, cushioned footbeds, and customizable fit options keep feet dry and reduce friction. A snug, personalized fit prevents blisters and hot spots, supporting productivity and comfort across tough shifts.

Custom Vs. Stock: Which Type Of Lineman Boot Is Right For You?

Choosing the best boots for lineman work involves balancing unique needs with trusted standards. Whether your job demands long hours on rough terrain or the highest level of safety and comfort, selecting between custom and stock boots will impact your everyday performance and satisfaction. Let’s break down what each option offers—and how to determine the best fit for your work life.

The Case For Custom Lineman Boots

Custom boots cater to the individual. They are designed based on precise foot measurements, often considering any specific concerns, like high arches, wide feet, or orthotic compatibility. Craftspeople build these boots with your chosen materials, hardware, and sometimes even sole construction, which can be critical for linemen working in extreme environments.

- Personalized Fit: Each element, from the height of the upper to the width of the toe box, can be tailored for maximum comfort and support, reducing the risk of hot spots and fatigue.

- Material Selection: Premium leathers and reinforced stitching can be selected for your particular job hazards, offering both durability and peace of mind.

- Unique Requirements: Extra support can be integrated into custom designs for those on uneven or hazardous terrain, enhancing safety in challenging conditions.

This artisan approach often results in a higher upfront investment and a longer lead time. Still, many professionals find the long-term benefits—unrivaled comfort, longevity, and the pride of a one-of-a-kind boot—well worth the wait.

When Stock Lineman Boots Make Sense

On the other hand, stock boots represent the proven workhorses of the trade. Built from time-tested templates, they are carefully crafted to meet the broader needs of linemen, offering ready-to-ship solutions without the wait for customization.

- Immediate Availability: When you need boots fast, stock options let you get to work without delay.

- Refined Designs: These boots are the product of decades—sometimes generations—of innovation. Many brands have spent years perfecting their lasts and materials for demanding jobs.

- Consistent Performance: With standard sizing and construction, stock boots are often easier to replace and maintain, making them a reliable choice for teams that require dependable uniformity.

While stock boots may not match your foot as perfectly as a custom pair, advances in ergonomic design mean many find them highly supportive right off the rack.

Factors To Consider

Choosing between custom and stock boots involves considering your priorities: foot shape, environment, anticipated conditions, and budget. Are you seeking the ultimate tailored experience, or do you need tried-and-true durability you can trust immediately? This decision is a critical step toward having the best boots for lineman work, ensuring safety and comfort as you take on every demanding day.

Top Materials Used In Linemen Boots

Regarding reliable performance on rugged terrain, the raw materials used in linemen boots are the foundation of safety and endurance. Every element, from the leather uppers to the hardware, is chosen for maximum longevity, support, and comfort—essential qualities for those who work at heights and in unpredictable environments.

Full-Grain Leather

Full-grain leather remains the gold standard in linemen boots. Its tightly packed fibers maintain the hide’s natural strength, making boots highly resistant to abrasions, punctures, and weathering. This form of leather also becomes more comfortable over time, molding to the shape of the wearer’s foot. Its breathability helps regulate temperature, which is crucial for long work hours.

Heavy-Duty Outsoles

The soles of a lineman’s boot must offer unbeatable grip and resilience. Vibram rubber—widely used for its slip resistance and ability to perform on oily, uneven, or muddy surfaces—is a frequent choice. Some boots feature composite or puncture-resistant midsoles for added protection against sharp objects and electrical hazards.

Supportive Shanks And Linings

A robust shank, often crafted from steel or advanced composite materials, is sandwiched between the outsole and insole to provide crucial arch support and resist twisting on rungs or rough ground. Quality linings, like moisture-wicking natural leather or specialized synthetics, help maintain dryness and prevent hot spots even during demanding climbs.

Corrosion-Resistant Hardware

Eyelets, hooks, and lacing hardware are constantly stressed and exposed to the elements. Nickel-plated brass or stainless steel components are commonly selected for their durability and rust resistance, ensuring that boots remain reliable season after season.

How To Properly Break In Your New Boots

A well-constructed pair of lineman boots is an investment in comfort and safety for years to come—but they do require proper breaking in. Rushing the process, or skipping crucial steps, can risk blisters, pain, and even long-term foot issues. Here’s how to let craftsmanship and patience work together so your boots mold seamlessly to your feet.

Start Slow: Gradual Wear Pays Off

When your boots first arrive, resist the urge to immediately put them through a full shift. Start by wearing your new boots indoors for short periods. This allows the leather to begin conforming to your foot shape without the stress of an all-day workload. Increase each day's duration for one to two weeks as the leather and insole gradually flex and adapt.

Wear The Right Socks

The socks you choose during break-in make a difference. Opt for medium-thick, moisture-wicking boot socks—these provide cushioning and keep your feet comfortable. High-quality socks also prevent excessive friction, one of the biggest causes of break-in blisters.

Condition The Leather

Quality leather needs some help early on. Apply a light coat of boot oil or conditioner to soften the leather fibers, especially in high-flex areas such as the vamp and around the ankle. Use only products recommended for your boot’s leather type to avoid damage or discoloration.

Address Pressure Points

If you notice any hot spots or stiff areas, don’t ignore them. Try using a wooden boot stretcher or gently massaging those areas to help the leather loosen. You can also try the old trick of wearing your boots with two pairs of socks for short indoor sessions—just make sure not to overdo it, as this can cause stretching or discomfort.

Let Them Rest

Don’t wear your new boots two days in a row during break-in. Leather needs time to dry out and decompress between wears. Allowing the shoes to rest helps maintain their shape and promotes a more even mold to your feet.

Trust The Process

Every craftsman knows: patience is non-negotiable in pursuit of true quality. With each step, your boots will feel less like something you put on and more like an extension of your own stride. Once properly broken in, the difference is unmistakable—comfort and support, mile after mile.

Maintenance Tips To Extend Boot Lifespan

A lineman’s boots aren’t just a piece of equipment—they’re a vital investment in everyday safety and performance. Regular care extends the life of this investment, ensuring boots maintain their structural integrity, protective capabilities, and comfort across many demanding shifts. Below are essential maintenance steps to prepare your boots for the most challenging terrain.

Clean After Every Shift

Dirt, mud, and debris can break down materials and stitching over time. After each use—especially after working in wet or muddy conditions—wipe off excess dirt with a soft brush or damp cloth. For stubborn grime, use lukewarm water and a mild soap, but avoid soaking the boots to protect the leather and interior structure.

Condition the Leather

Leather loses its oils over time, particularly in rough outdoor settings. Replenish moisture and flexibility by periodically applying a high-quality leather conditioner. Pay extra attention to flex points and seams, which are the most prone to drying and cracking. Conditioning preserves the leather’s resilience and prevents premature aging.

Dry Thoroughly, Never With Direct Heat

After exposure to moisture, allow boots to dry naturally at room temperature. Avoid placing them next to heaters or using blow dryers—direct heat can shrink and warp the leather, undermining comfort and protection. Stuffing boots with newspaper or using cedar shoe trees helps absorb excess moisture and maintain their shape.

Inspect And Replace Laces And Hardware

Boot laces are a frequent failure point and should be checked regularly for fraying or breakage. Similarly, inspect eyelets, hooks, and other hardware for signs of wear or rust. Replace damaged components promptly to ensure secure fit and lasting performance.

Rotate And Rest

Let's alternate between two pairs of boots. Rotating allows each pair to fully air out and recover between shifts, which can extend their serviceable life and maintain optimal comfort.

Final Thoughts

In a job where your footing could mean the difference between getting home safe or not, the right pair of lineman boots isn't just important—it’s essential. From climbing poles in the rain to navigating uneven ground under heavy load, linemen demand gear that offers unwavering protection, comfort, and resilience.

At Nicks Boots, we’ve built our reputation on delivering footwear that meets that challenge head-on. Whether you opt for a custom pair tailored to your every step or a trusted stock model, choosing the proper boots is an investment in your safety, performance, and peace of mind. Put simply: your boots should work as hard as you do.

Read also:

Frequently Asked Questions About Best Boots For Linemen

How does a steel toe protect linemen's feet?

A steel toe serves as a crucial barrier against impact and compression hazards. For linemen, who frequently work around heavy equipment, climbing hardware, and unpredictable terrain, a steel toe cap helps protect the foot from dropped tools, falling objects, and accidental compressions.

Why is ankle support important for linemen's boots?

Linemen often navigate challenging terrain, ascend utility poles, and operate in environments where stability is paramount. Superior ankle support prevents rolling, sprains, and fatigue, making it an essential feature for safety and endurance on the job.

How do lineman boots differ from other work boots?

Lineman boots stand apart due to their specialized construction. They typically feature taller shafts for added leg support, reinforced shanks for climbing, heavy-duty lacing for a secure fit, and rugged outsoles for optimal grip on poles and ladders. Unlike standard work boots, lineman boots are built “from start to finish” with heightened attention to durability, support, and electrical hazard protection.

What is the purpose of a lineman shank in boots?

A lineman shank is an internal support piece that adds rigidity and structure to the boot’s sole, making it easier to climb poles and provide stable footing on ladders. The shank distributes weight evenly, reduces foot fatigue, and helps prevent punctures.

How much insulation do linemen need in their boots?

The level of insulation depends on the climate and intended use. Linemen working in cold or variable weather benefit from boots with sufficient thermal insulation to prevent numbness and frostbite, while those in warmer climates may prioritize breathable, lightweight designs.

Are waterproof boots necessary for linemen?

Waterproof boots are highly recommended for linemen, as they often face wet, muddy, or unpredictable outdoor conditions. Effective waterproofing preserves foot comfort, prevents moisture-related injuries, and extends the life of the boot.