Key Takeaways:

- Material Quality Matters: Full-grain leather and premium rubber outsoles are essential for ensuring durability, breathability, and resistance to wear over time.

- Match Boots to Your Job: Selecting features like reinforced toes, slip-resistant soles, or insulation tailored to your industry ensures safety and longevity.

- Proper Care Extends Lifespan: Regular maintenance, such as cleaning, conditioning, and proper storage, preserves your boots’ performance and durability for years.

What’s the secret to finding work boots that survive years of tough shifts, unpredictable conditions, and heavy-duty work? Too often, buyers settle for boots that fall apart after a few months, leaving their feet—and wallets—unprotected. Durable work boots aren’t just footwear; they’re a critical tool for safety, productivity, and comfort on the job.

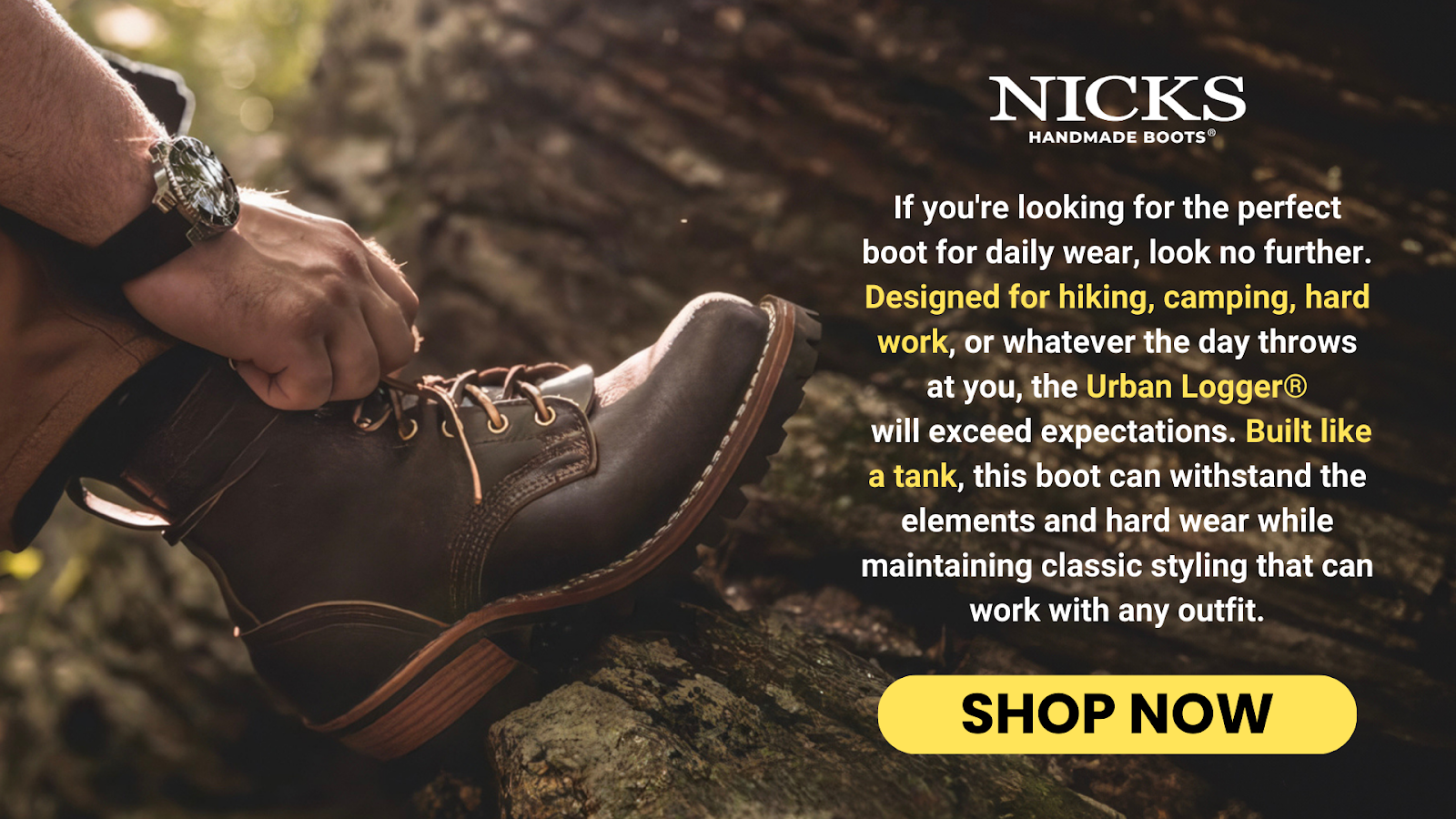

At Nicks Boots, we know durability because we build it. With decades of expertise, our boots are handcrafted from premium full-grain leather and designed to last in the harshest conditions. They’re not just boots—they’re an investment in quality.

In this piece, we’ll explore how to select work boots that stand the test of time and are tailored to your industry’s unique demands. You’ll also discover why superior craftsmanship, like that in Nicks Boots, is essential for achieving unmatched durability and comfort.

Understanding Durability In Work Boots

Durability in work boots is a combination of material quality and construction excellence. Boots designed for tough environments must use high-grade materials, like full-grain leather, which offers natural resistance to wear, water, and abrasion. Unlike synthetic materials, full-grain leather develops a unique patina over time, enhancing its appeal and strength even under harsh conditions. The sole and stitching also play a critical role, as poorly constructed seams or low-quality rubber can cause premature wear.

Equally important is the structural design of the boots. Durable work boots feature reinforced soles, solid midsoles, and rugged outsoles, providing traction and stability in challenging environments. A well-designed boot lasts longer and protects the wearer from injuries caused by slips or uneven terrain. Durability goes beyond just lasting longer—it’s about keeping you safe, comfortable, and efficient no matter the job.

Key Features To Look For In Durable Work Boots

Choosing durable work boots means understanding the critical elements that ensure long-lasting performance and reliability. Each feature keeps you comfortable, safe, and efficient, from material quality to design specifics during tough jobs. Let’s break down the key features you should prioritize when shopping for the most durable work boots:

- Full-Grain Leather: Full-grain leather is the gold standard for work boots. It offers unmatched durability, resisting abrasions, water, and general wear over time. Unlike synthetic materials, it adapts to the environment, providing natural breathability to keep your feet cool and dry. The leather also develops a unique patina, adding character while maintaining strength.

- Sturdy Outsoles: A durable outsole is essential for traction and protecting against harsh surfaces. Look for high-quality rubber or Vibram soles, which resist oil, heat, and chemicals while offering excellent grip on slippery or uneven terrain. Reinforced midsoles add shock absorption, reducing strain during long workdays and ensuring stability.

- Strong Stitching and Construction: Well-made boots feature double or triple-stitched seams, which prevent splitting under pressure. The Goodyear welt construction is a preferred method, ensuring the sole stays securely attached while allowing for resoling when needed. This design significantly extends the boot’s lifespan, making it a worthwhile investment.

- Comfort and Support Features: Durability doesn’t mean sacrificing comfort. Look for arch support, cushioned insoles, and structured heel cups that maintain foot alignment and reduce fatigue during long wear hours. Proper support enhances comfort and ensures the boot’s materials last without collapsing or deforming.

Matching Boots To Your Industry Needs

Not all industries demand the same features in a work boot. The right pair can significantly enhance safety, performance, and comfort, so choosing boots tailored to your job's specific challenges is essential. Let’s break down how to match boots to different work environments for optimal durability and functionality:

Construction And Heavy-Duty Trades

Construction sites present numerous hazards, from sharp nails to heavy equipment. Boots with steel or composite toe caps offer essential protection against impact, while thick, slip-resistant rubber outsoles ensure stability on uneven surfaces. Waterproofing and electrical hazard ratings are valuable features, particularly in wet or hazardous conditions. Additional cushioning and arch support can make long days on concrete more bearable.

Logging And Forestry

Loggers work in some of the harshest environments, requiring boots built for rugged terrain. High-traction lug soles ensure stability on muddy, uneven ground, while puncture-resistant midsoles protect against sharp objects. Full-grain leather uppers provide durability and resistance to abrasions from brush or debris, while reinforced toe areas offer added safety from falling logs or tools.

Mechanics And Industrial Workers

Industrial workers and mechanics need boots that combine durability with resistance to oil, grease, and chemicals. Rubber outsoles with oil-resistant properties prevent slips in shop settings, while breathable full-grain leather keeps feet comfortable during long shifts. A structured heel cup and cushioned insole are essential for standing or kneeling on hard surfaces for extended periods.

Outdoor Labor And Agriculture

Workers in agriculture or outdoor labor require boots that balance durability with weather resistance. Waterproof full-grain leather and rubber outsoles with deep treads provide excellent grip and protection in wet, muddy conditions. Insulated options may be necessary for colder climates, while breathable designs prevent overheating in warm weather.

Top Materials For Long-Lasting Boots

The materials used in work boots are critical to their durability and performance. Choosing boots made from high-quality components ensures they can withstand wear and tear, protect your feet, and remain comfortable over time. Let’s take a closer look at the top materials that set long-lasting work boots apart:

- Full-Grain Leather: Full-grain leather is the ultimate choice for durability in work boots. This leather is taken from the outermost layer of the hide, retaining its natural strength and resistance to abrasions, water, and wear. It also offers excellent breathability, keeping your feet cool while adapting to your foot shape over time for a personalized fit.

- Rubber Outsoles: Rubber outsoles are known for their resilience and versatility, making them ideal for rugged work environments. These outsoles resist slipping, oil, and heat, ensuring safety and durability on various terrains. Vibram soles, in particular, are popular for their exceptional grip and long lifespan, even under heavy use.

- Reinforced Toe Caps: Toe caps made of steel or composite materials are essential for protecting against heavy impacts and compression. While steel toes offer maximum strength, composite alternatives are lighter and resist temperature changes, making them ideal for varied climates and work settings. These reinforcements prevent premature wear in high-stress areas of the boot.

- Shock-Absorbing Midsoles: Midsoles made of PU (polyurethane) or EVA (ethylene-vinyl acetate) provide crucial support and shock absorption. They help reduce fatigue during long hours of standing or walking while maintaining the structural integrity of the boot. These materials are also highly durable, ensuring the boot maintains its performance over time.

Caring For Your Work Boots To Extend Their Lifespan

Even the most durable work boots require proper care to last for years. Regular maintenance keeps your boots looking great and preserves their performance and protective features. Here’s how you can protect your investment and extend the lifespan of your work boots:

Clean Them Regularly

Dirt, mud, and debris can break down the leather and stitch over time. After each use, wipe your boots with a damp cloth to remove surface grime, and use a soft brush to reach crevices. For tougher stains, use a leather-specific cleaner that protects the material without causing damage.

Condition The Leather

Leather can dry out and crack if not properly moisturized. Use a high-quality leather conditioner every few weeks to keep the material supple and wear-resistant. Conditioning also helps maintain the water-resistant properties of full-grain leather, keeping your feet dry in wet conditions.

Store Properly

Improper storage can lead to deformed boots and premature wear. Always store your boots in a cool, dry place, away from direct sunlight and heat sources that can dry out the leather. Consider using boot trees or stuffing the boots with paper to maintain their shape when not used.

Replace Worn Outsoles

Over time, even the most durable outsoles will wear down from use. Replace worn-out soles promptly to maintain traction and support, preventing further damage to the boots. Choosing boots with Goodyear welt construction makes resoling easier and more cost-effective.

Why Nicks Boots Stand Out In Durability

When it comes to durability, Nicks Boots set the gold standard for hard-working professionals. Handcrafted from premium full-grain leather, these boots are designed to withstand the rigors of demanding industries like construction, logging, and manufacturing. Built with Goodyear welt construction, they offer exceptional strength and the ability to be resoled, extending their lifespan far beyond mass-produced options.

Nicks Boots emphasizes quality and craftsmanship, ensuring each pair provides superior support and protection. It combines rugged materials, expert design, and unmatched attention to detail, making it a true investment in long-term reliability. For buyers seeking comfort, safety, and longevity, these boots are a trusted choice that pays off at every step.

Final Thoughts

Choosing the most durable work boots is about more than finding footwear—it’s about ensuring your safety, enhancing your productivity, and making an investment that stands the test of time. Durable boots are critical for workers in demanding industries, offering the reliability and protection needed to perform your best in challenging environments. The right pair shields you from hazards and keeps you comfortable through long, grueling days, proving their worth with every step.

At its core, durability in work boots reflects a commitment to quality—both in design and materials. When you prioritize craftsmanship and tailor your choice to the unique demands of your industry, you’re not just buying boots; you’re equipping yourself for success. Nicks Boots exemplifies this principle, blending traditional techniques with modern durability to provide boots that are more than a purchase—they’re a partner in your workday.

Read also:

Frequently Asked Questions About Most Durable Work Boots

How do I determine if a work boot is durable before buying it?

Check for premium materials like full-grain leather and features like Goodyear welt construction. Customer reviews and manufacturer warranties can also provide insight into durability.

Are steel-toe boots always more durable than composite-toe boots?

Not necessarily; durability depends on the boot’s overall construction and materials. Steel toes provide strong impact protection, but composite toes are lighter and resist wear in extreme climates.

Do durable boots require a break-in period?

Yes, especially boots made of full-grain leather. The material needs time to conform to your feet, but once broken in, it provides exceptional comfort and longevity.

What makes full-grain leather better than other materials?

Full-grain leather retains the hide's natural strength, making it resistant to wear and tear. It’s breathable and ages well, developing a rich patina.

Can lightweight boots be as durable as heavier ones?

Yes, if they are constructed with high-quality materials like composite toes and Vibram outsoles. However, lighter boots may lack some of the protective features of heavier options.

How often should I replace durable work boots?

It depends on usage and care; well-maintained boots can last several years. Replace them when the soles wear out, or the structural integrity is compromised.

Are insulated boots less durable than non-insulated ones?

No, insulation doesn’t affect durability as long as the outer materials are high-quality. Insulated boots are ideal for colder climates but require proper maintenance to prevent damage.

What kind of sole provides the best durability for work boots?

Rubber soles, especially Vibram soles, are highly durable and provide excellent grip and resistance to wear. Look for soles with deep treads for added traction.

Can waterproofing affect the durability of work boots?

Yes, boots with waterproofing features often last longer in wet conditions by preventing material damage. However, they should be regularly conditioned to maintain their water resistance.

Are handmade boots more durable than factory-made ones?

Handmade boots often use superior materials and craftsmanship, leading to longer-lasting performance. They are also easier to repair, extending their lifespan even further.