Key Takeaways:

- Advanced Material Technology: Logging boots incorporate advanced materials such as full-grain leather and heavy-duty rubber compounds, ensuring durability and water resistance critical for logging environments.

- Enhanced Ergonomic Features: Modern logging boots emphasize ergonomic features like padded insoles and flexible lacing systems, which adapt to the foot's natural swelling throughout the day, maintaining comfort and fit.

- Industry-Specific Design: Designed specifically for the logging industry, these boots feature high-cut designs and reinforced side panels to offer extra protection against underbrush and other occupational hazards common in forested areas.

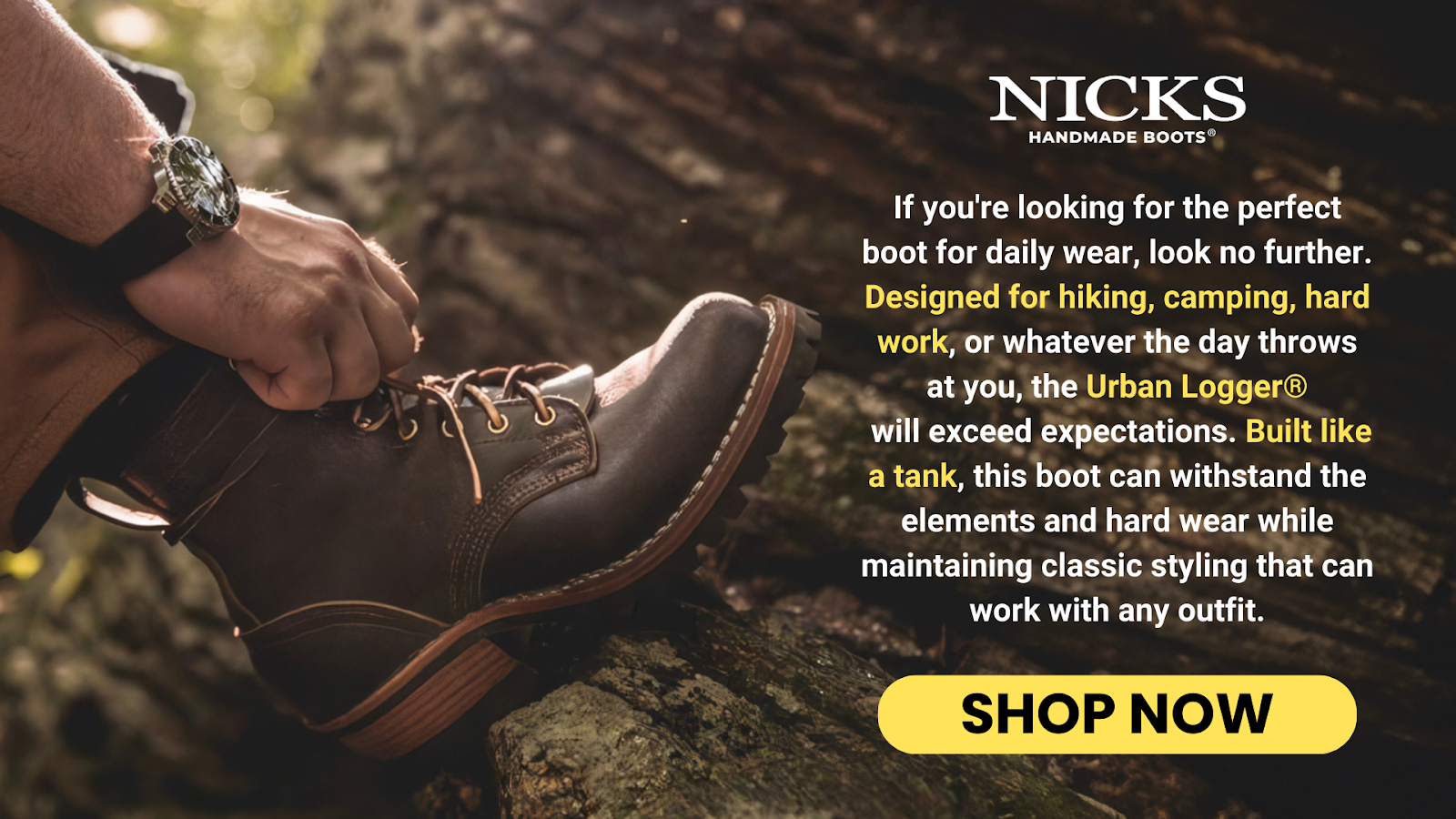

At Nicks Boots, we don't just make footwear; we craft the backbone of the rugged and reliable lifestyle of logging professionals. Known for our uncompromising quality and craftsmanship, our logging boots stand as a testament to our commitment to excellence. Each pair is a blend of tradition, innovation, and engineering designed to meet the unique challenges of logging work.

In this piece, we will explore the essential features of logging boots, including ankle support, traction, and protection, and guide you on choosing the right boots for both durability and comfort. We’ll also share maintenance tips to ensure your boots last, and offer insights from real-world users who testify to the quality and resilience of our products.

Key Features Of Logging Boots

Ankle Support

Our logging boots feature robust ankle support designed specifically for the demands of rugged terrain. The carefully structured support system includes both high-cut designs and additional ankle padding, ensuring stability and comfort even on the most uneven ground. Reinforced side panels increase resistance against impacts and strains, crucial in preventing injuries. This support allows for prolonged wear without compromising on safety or comfort, ideal for professionals who spend long hours on their feet.

Superior Traction

The outsoles of our logging boots are built with advanced traction technology, ideal for maintaining a secure footing on slippery surfaces. Using heavy-duty rubber compounds, the tread patterns are optimized for maximum grip in various conditions, including mud, rain, and snow. The depth and spacing of the treads prevent debris build-up, ensuring consistent traction. This design feature is vital for preventing accidents in environments where surfaces can be unpredictably slick.

Protection In Rugged Environments

Our logging boots are fortified with features like steel toes and puncture-resistant soles to offer unmatched protection. The steel toe caps are designed to withstand significant impacts and compression forces, meeting or exceeding safety standards. Puncture-resistant materials integrated into the soles shield the foot from sharp objects, ensuring that nothing breaks through the underfoot. Additionally, the boots are crafted from premium, abrasion-resistant leather that holds up against harsh conditions, extending the life of the footwear.

Choosing The Right Logging Boots For Durability And Comfort

Evaluate Materials And Construction

The choice of materials is critical for the durability of logging boots. Opt for boots made from full-grain leather, which not only offers superior toughness but also provides excellent water resistance. Boots should be assembled with robust stitching techniques such as triple or double stitching to enhance their structural integrity. This construction prevents the boots from falling apart under the stress of rugged outdoor work environments. High-quality hardware, like brass eyelets and hooks, also contributes to the longevity of the boots.

Comfort Features

Comfort in logging boots is essential for reducing fatigue during long workdays. Seek features like padded insoles, which provide cushioning and support to the feet. Additionally, look for boots with a good arch support system and a contoured footbed, which help in distributing weight evenly and reducing strain on the feet. Breathable linings can help manage moisture and keep the feet dry, thereby preventing blisters and other discomforts. A well-padded collar adds comfort and protects the ankles.

Lacing System

The lacing system of your logging boots plays a significant role in ensuring a secure and comfortable fit. It should allow for easy adjustments, enabling the wearer to tighten or loosen the fit according to their needs throughout the day. Boots with durable, non-slip laces ensure that they stay tied even in tough conditions, preventing potential tripping hazards. The design of the eyelets should facilitate smooth lacing without causing friction. A flexible lacing system accommodates changes in foot size due to natural swelling throughout the day, maintaining comfort and fit.

Maintenance Tips For Logging Boots

- Regular Cleaning: Proper maintenance of logging boots begins with regular cleaning. Remove dirt and debris after each use by wiping the boots with a damp cloth and using a soft-bristled brush for tougher grime. This prevents the accumulation of materials that can degrade the leather over time. For deeper cleaning, use a leather cleaner designed for use with full-grain leather to maintain the material’s integrity and appearance.

- Conditioning the Leather: Conditioning your logging boots is essential to keep the leather supple and prevent it from drying out and cracking. Apply a quality leather conditioner every few months, or more frequently if the boots are used in particularly harsh conditions. This not only extends the life of the boots but also enhances their water resistance and overall durability.

-

Proper Storage: Store your logging boots in a cool, dry place away from direct sunlight when not in use. Humidity and heat can warp leather and degrade adhesives used in boot construction. Using boot trees can help maintain the shape of the boots and prevent creasing.

Waterproofing: To further protect your boots, apply a waterproofing treatment suited for leather boots. This is especially important if you frequently work in wet conditions. The waterproofing not only keeps your feet dry but also protects the leather from water damage. - Check for Wear and Tear: Regularly inspect your boots for signs of wear and tear, such as loose soles or damaged stitching. Addressing these issues early can prevent them from becoming major problems, ensuring your boots remain safe and functional for as long as possible.

Sustainable Practices In Logging Boot Production

Eco-Friendly Materials

In an effort to reduce environmental impact, the production of logging boots has seen a shift towards more sustainable materials. Manufacturers are now utilizing recycled rubbers and plastics, as well as natural fibers like organic cotton, in their boot designs. These materials are not only less harmful to the environment but are also durable and capable of withstanding the harsh conditions typical of logging environments. The integration of these materials helps reduce waste and promotes a cycle of sustainability within the industry.

Reducing Chemical Use

Reducing chemical use in the production of logging boots is a significant step towards greener manufacturing processes. Companies are opting for water-based adhesives, dyes with lower volatile organic compounds (VOCs), and non-toxic treatments for waterproofing. These changes help in minimizing the ecological footprint of their production lines while ensuring that the products are safer for both the workers involved in their manufacture and the end-users.

Impact On Product Quality And Safety

Adopting sustainable practices does not compromise the quality and safety of logging boots; in fact, it often enhances them. Boots made with eco-friendly materials tend to offer improved breathability and comfort. Additionally, the rigorous standards for environmentally friendly products ensure that these boots meet high durability and safety criteria, making them suitable for the demanding conditions of logging work.

The Evolution Of Logging Boots: From Past To Present

Early Beginnings

Logging boots have come a long way from their humble beginnings. Originally, they were simple leather shoes with minimal protection and support for loggers working in rugged conditions. As logging techniques and machinery evolved, so did the need for more durable and protective footwear. Early improvements included thicker soles and higher cuts to protect against underbrush and snake bites.

Technological Advancements

Throughout the 20th century, advancements in materials science led to the incorporation of steel toes and improved sole materials such as rubber and polyurethane. These changes significantly enhanced the durability and safety of the boots. The development of waterproofing techniques and breathable fabrics also made boots more comfortable and practical for various weather conditions.

Modern Innovations

Today's logging boots are a product of decades of innovation, featuring lightweight composite materials for protection without the weight of traditional steel. Modern boots also emphasize ergonomic design to support the wearer's foot and ankle effectively, reducing fatigue and increasing comfort. Furthermore, contemporary designs include advanced lacing systems that provide a secure fit and ease of use.

Final Thoughts

Logging boots today must combine quality, safety, and innovation to meet the rigorous demands of the industry. These boots are designed with features like robust ankle support, advanced traction, and superior protection, ensuring both the safety and comfort of professionals working in challenging environments. Additionally, a shift toward sustainable manufacturing practices demonstrates a commitment to reducing environmental impacts.

By incorporating eco-friendly materials and minimizing chemical use, manufacturers not only appeal to environmentally conscious consumers but also uphold the durability and safety essential for logging work. This comprehensive approach marks a significant evolution in the industry, adeptly meeting both professional needs and environmental standards.

Read also:

Frequently Asked Questions About Logging Boots

What is the history of logging boots?

Logging boots have evolved from simple leather shoes to highly technical gear with features like steel toes and advanced traction. Originally designed for basic protection, today's boots incorporate decades of innovation to meet the rigorous demands of logging.

How should logging boots fit to ensure maximum comfort and safety?

Logging boots should fit snugly around the heel and instep, with enough room in the toe box to wiggle your toes. Proper fit prevents blisters and allows for swelling, which is common during long workdays.

Can logging boots be used in other industries or are they specific to logging?

While logging boots are specifically designed for the logging industry, their robust construction and safety features make them suitable for construction, forestry, and other outdoor work environments requiring protective footwear.

What are the most important safety features to look for in logging boots?

Key safety features include steel toe caps, puncture-resistant soles, and slip-resistant outsoles. These elements ensure protection against common hazards such as heavy impacts, sharp objects, and slippery surfaces.

How do I maintain my logging boots to extend their lifespan?

Regular cleaning, conditioning the leather, waterproofing, and storing the boots in a cool, dry place are essential steps to maintain and extend the lifespan of logging boots.

Are there any innovations in logging boots that help reduce environmental impact?

Yes, modern logging boots are increasingly made with sustainable materials like recycled rubber and organic cotton. Additionally, manufacturers are using water-based adhesives and low-VOC dyes to minimize environmental impact.

What makes a logging boot's traction superior for rugged environments?

The traction in logging boots is designed with deep, wide-spaced treads and durable rubber compounds to maintain grip in mud, snow, and other slippery conditions, preventing slips and falls.

How often should logging boots be replaced?

The replacement schedule for logging boots depends on usage intensity, but generally, they should be inspected regularly for wear and replaced if there are signs of significant wear on the soles or upper, or if the safety features are compromised.

What advancements in materials have improved the comfort of logging boots?

Advances such as breathable fabrics, ergonomic design, and the use of lightweight composite materials for protection help reduce fatigue and enhance comfort throughout the workday.

How do the ankle support features in logging boots enhance worker safety?

Ankle support in logging boots includes high-cut designs and additional padding, which help stabilize the foot and prevent injuries by supporting the ankle against the strains of uneven terrain.